Modeling Behavior : Dragonfly Structure

Arch 655 Parametric Modeling in Design

Spring 2016

Instructor: Dr. Wei Yan

Texas A&M University

Spring 2016

Instructor: Dr. Wei Yan

Texas A&M University

Background

This project utilizes the logic of dragonfly structure to design a pavilion. According to Mingallon and Ramaswamy (2011):

“ The morphology of the dragonfly wing is an optimal natural construction built by a complex patterning process, developed through evolution as a response to force flows and material organisation. The seemingly random variations of quadrangular and polygonal patterns follow multi-hierarchical organizational logics enabling it to alter between rigid and flexible configurations” .

“The

wings

of dragonflies are complex flexible aerofoils, whose deformations in flight are encoded

in the distribution of rigid and compliant components within their structure. The

wings have ‘smart properties’ adapted to deform automatically and appropriately

in response to the forces they receive . The multiple configurations of the

wing geometry could be understood by several factors, which influence the

deformation; namely plan form geometry, corrugations, flexural stiffness,

joints, mechanics, cambered infill membrane and hydraulics. These factors […]

complement one another and collectively provide the dragonfly wing with a

‘complex emergent behaviour’,

which is not the mere sum of the parts” .

Flow analysis (Mingallon and Ramaswamy , 2011)

Thickness distribution of the forewing of Sympetrum vulga- tum. (a) Thickness distribution of the veins. (b) Thickness distribution of the membranes source: (Lentink , 2010 )

Analytically modelled

spatial aerodynamic pressure and inertial load distribution over the forewing

area during

a stroke

in hovering flight source:

(Lentink , 2010 )

Spatial deformations (shown 10 times enlarged) of a flapping Sympetrum vulgatum wing during hovering flight. source: (Lentink , 2010 )

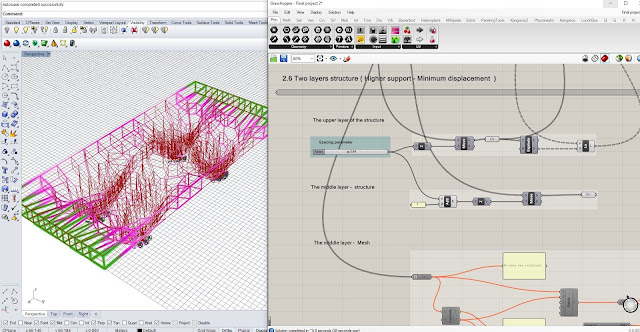

Modeling in Rhino and Grasshopper

First : Geometry

1. Start with a generic basic geometry : surface / Mesh

2. Deformation : deform that mesh by using Kangaroo physics-engine ( define the anchor points, the deformed forces )

3. Compare the two geometries together ( the original surface (A) vs. the deformed surface (B) ), and extract the faces of each surface (Mesh).

4. find the center point of each face , then measure the degree of changes between status A and B : Displacement , Strain value

5. Construct a domain for these values and dispatch faces into four groups

6. Control the density of faces

7. Construct two patterns of points distribution according to the deformation value of the mesh faces

8. Construct the cells by using voronoi structure

Second : Structural Optimization (Karamba3d)

1. Use the curves from the previous operation as an input here

2. Explode the curves to get the segments and the vertices , then convert them into beams (line to beam)

3. Define the support location and type , Loads , Cross section, Material and Joints

4. Assemble the model and Review the results

No comments:

Post a Comment